Time: 2019-11-30

Time: 2019-11-30  Views: 2189

Views: 2189

▼In order to facilitate further learning and sharing, we have organized and summarized the content of this issue and formed dry information for everyone. We hope that everyone can continue to charge and improve, and continue to accelerate on the path of our beloved SAP career.

Introduction to this issue’s guests:

With the widespread attention and industry development of German Industry 4.0 and Made in China 2025, the topic of intelligent manufacturing has always been one of the important topics in digital transformation. In recent years, SAP’s development and layout of smart factory solutions have also been increasing. The more perfect it is.

Everyone knows that the SAP ERP product S/4HANA is a widely used leading product in the industry. In fact, SAP MES has entered the Chinese market since 2010. With the continuous integration and development of products and SAP solutions, SAP MES has become more mature. , and is continuing to strengthen and improve its layout and development in smart factory solutions.

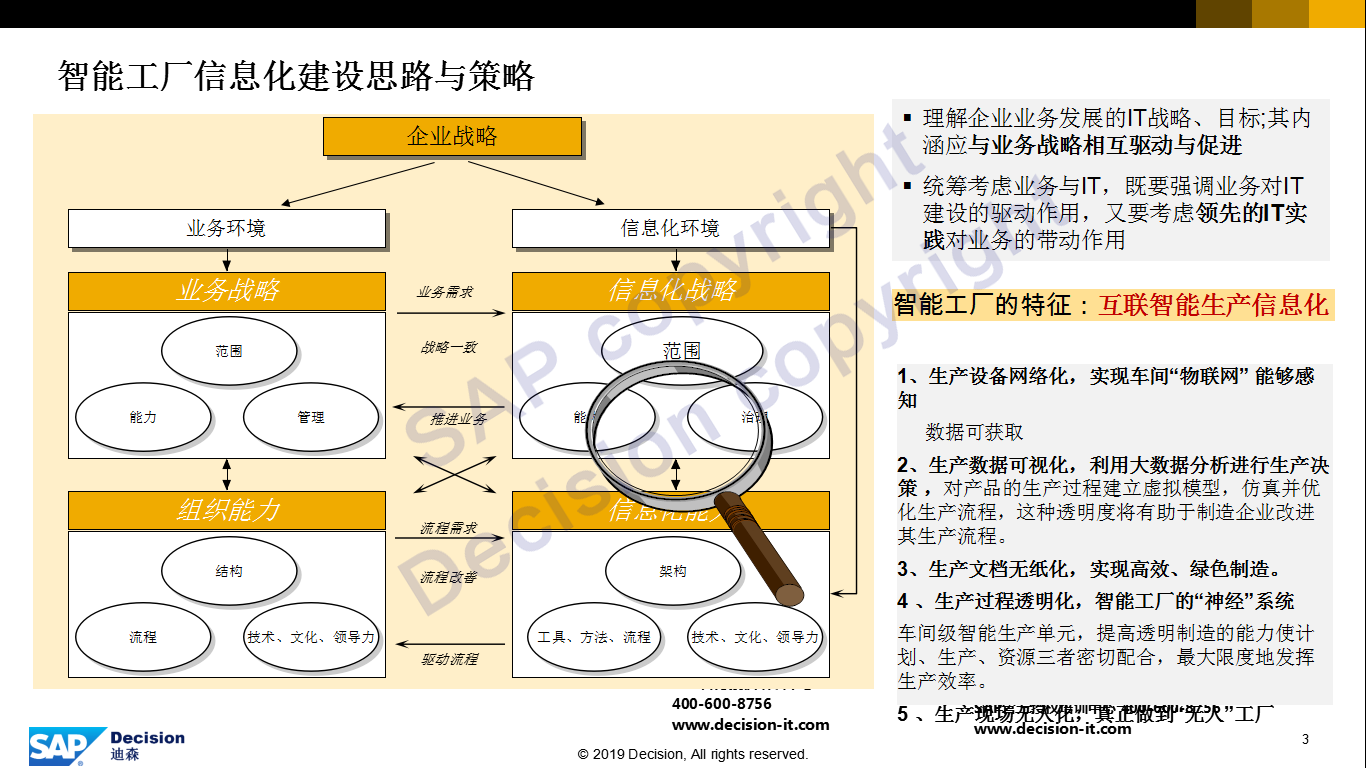

1.Smart factory information construction and ideas

Let’s first understand the relationship between corporate development strategy and smart factory construction:

- Understand the IT strategy and goals of enterprise business development; its connotation should drive and promote each other with the business strategy.

- When considering business and IT in an overall manner, we must not only emphasize the driving role of business in IT construction, but also consider the driving role of leading IT practices in business.

Generally speaking, the characteristics of smart factories are defined by SAP as interconnected intelligent production informatization. It has five characteristics:

1) The production equipment is networked to realize the "Internet of Things" in the workshop that can sense and obtain data.

2) Production data visualization, using big data analysis to make production decisions, establishing a virtual model of the product's production process, simulating and optimizing the production process. This transparency will help manufacturing companies improve their production processes.

3) Paperless production documents enable efficient and green manufacturing.

4) The production process is transparent and the "nervous" system of the smart factory. Workshop-level intelligent production units improve the ability of transparent manufacturing so that planning, production, and resources can work closely together to maximize production efficiency.

5) The production site is unmanned, truly becoming an “unmanned” factory.

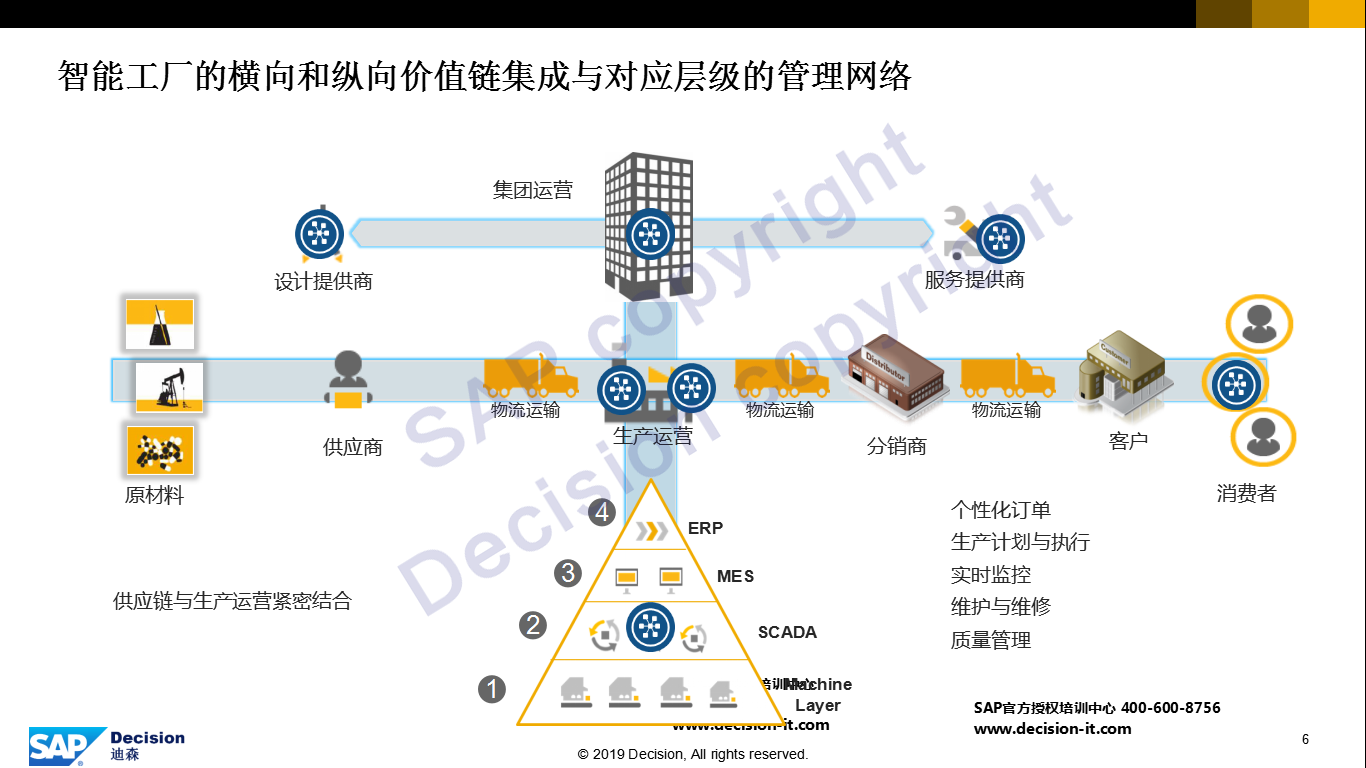

2. Horizontal and vertical value chain integration of smart factories and corresponding levels of management networks

Smart factories can be elaborated from two dimensions:

- From the perspective of the horizontal management value chain from raw materials to customers, and from the value creation dimension of the company's own production operations, the management focus of SAP MES is on all aspects of production operations. At the same time, SAP MES is not independent, but is integrated with the whole The horizontal end-to-end horizontal integration enables the supply chain to be closely integrated with production operations.

- The SAP solution fully possesses the characteristics of a smart factory, emphasizing the informatization of interconnected smart production.

3. Five “Interconnected” Scenarios of Intelligent Manufacturing

▲SAP defines five interconnection scenarios:

- First, in the traditional sense, it is an integration of vertical internal production operations within an enterprise from the workshop level to the business level;

- The second type is called smart device interconnection for production equipment;

- The third is the integration of downstream e-commerce with customers, that is, the integration of configuration and production with the direct needs of online customers, integrating customer needs with production links;

- The fourth is an internal manufacturing management system, including manufacturing execution management, production visualization, quality, Kanban management, etc.;

- The fifth type is the equipment cloud. During the entire production process, our production line equipment must continue to operate. To ensure the normal operation of the equipment during the production process, the equipment cloud must be considered.

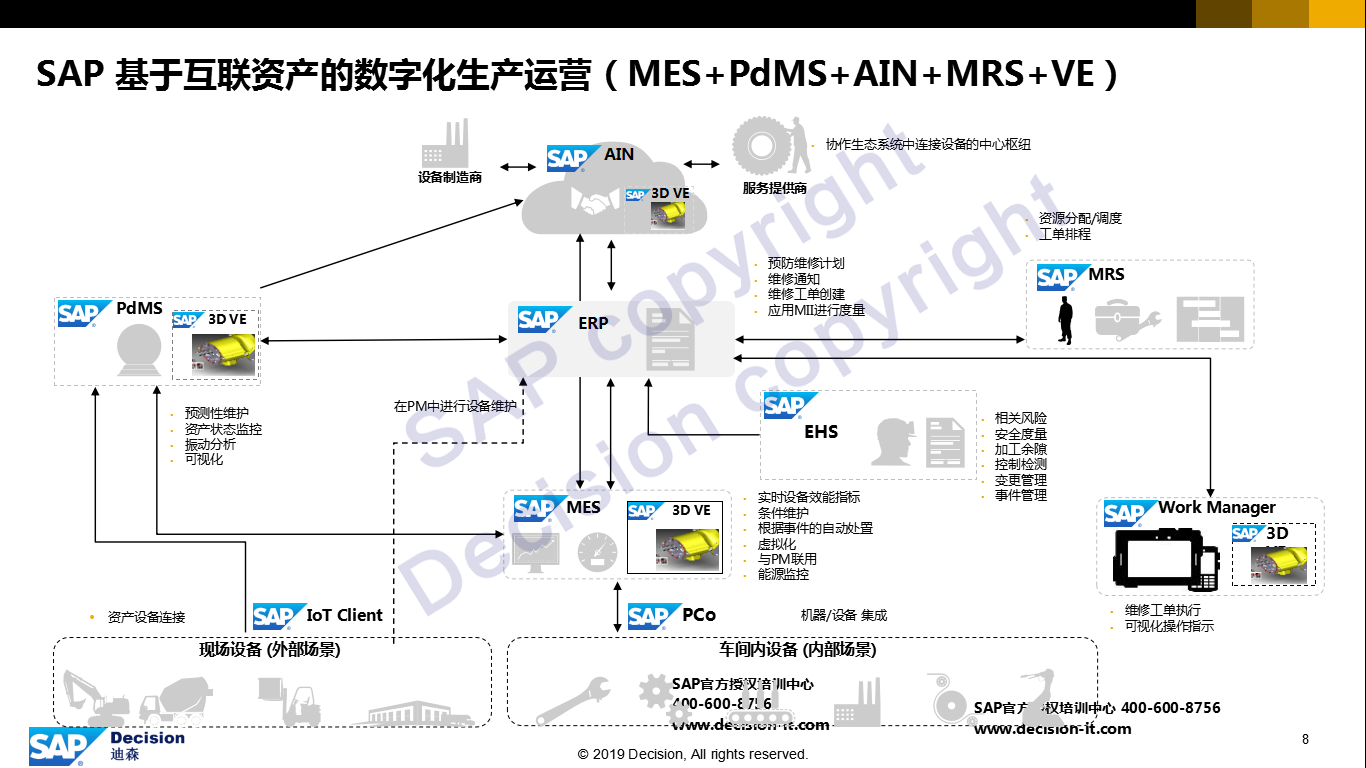

▲SAP’s solutions corresponding to these 5 scenarios are as follows:

From bottom to top: SAP IOT Client Internet of Things and equipment asset link solution, SAP PCo equipment integration adapter, SAP MES, SAP PDMS equipment predictive maintenance, SAP EHS safety supervision and environmental management, SAP Work Manager equipment mobile asset management, SAP MRS equipment or production line overhaul or maintenance resource planning and task management, and collaborative management of the top equipment asset network. and SAP VE, the 3D modeling technology used in each solution.

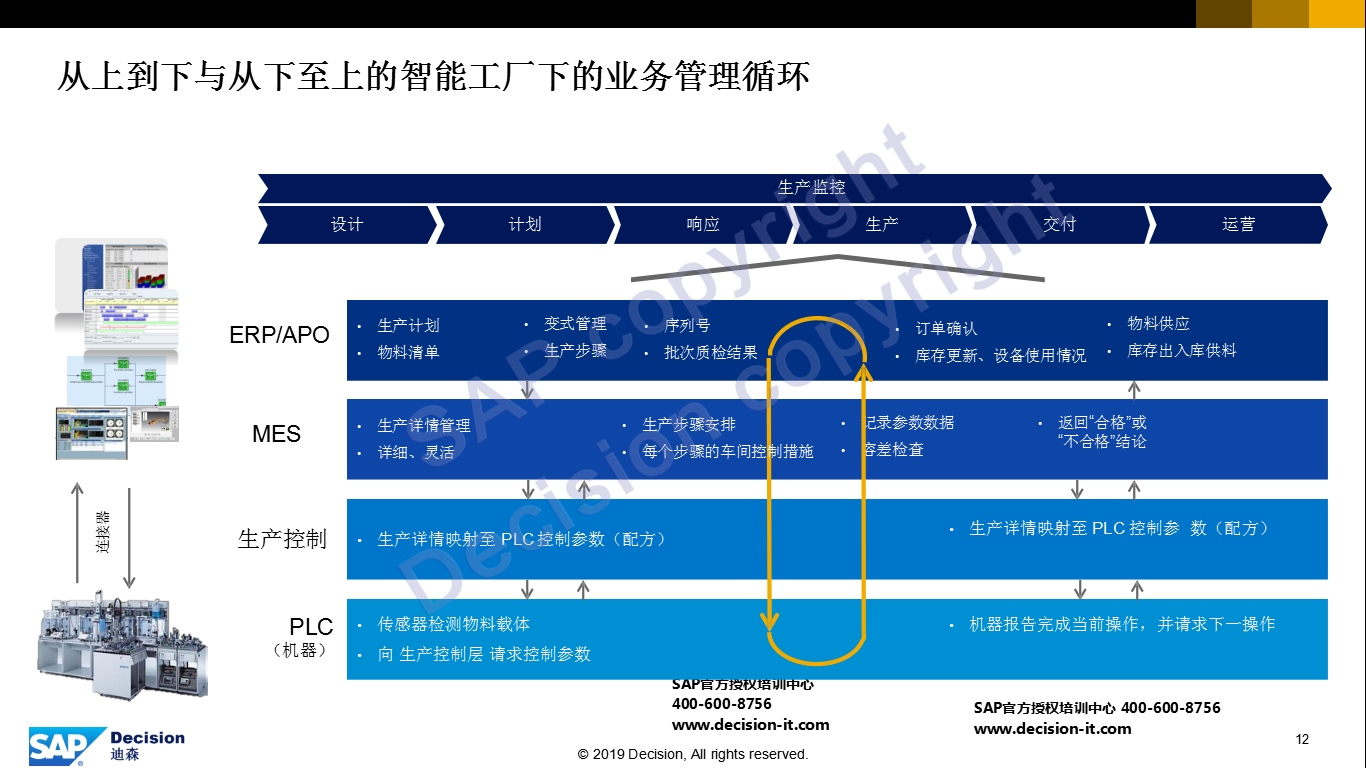

4. Business management cycle under the smart factory from top to bottom and bottom to top

From a vertical perspective, that is, the business management cycle under the smart factory from top to bottom and bottom to top, as can be seen from the above figure, MES is located on the third layer. No matter what type of MES product it is, it is divided into levels such as equipment layer, production control, MES, and ERP/APO. Through the downward release of plans, the production line production execution process is fed back to ERP in real time, and interacts with ERP's inventory management for material input and output.

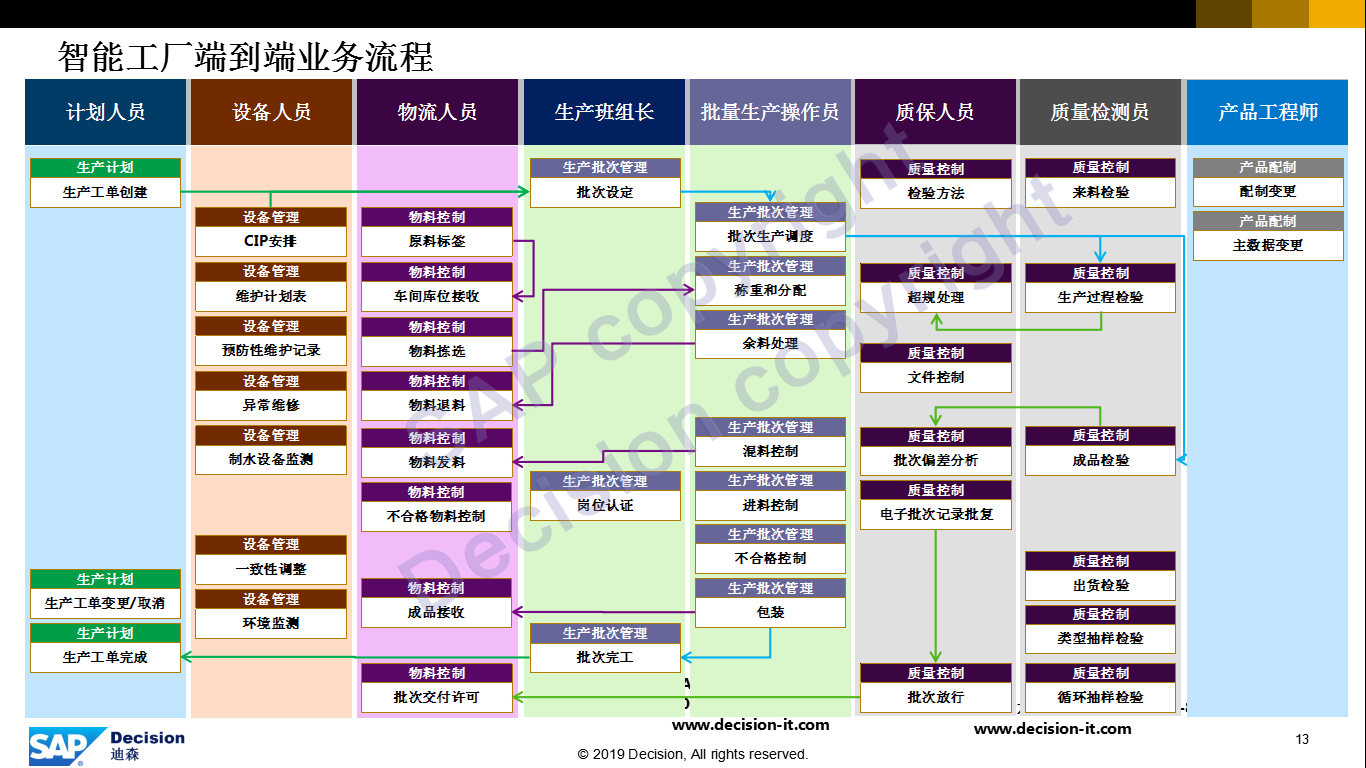

5. Smart factory end-to-end business process

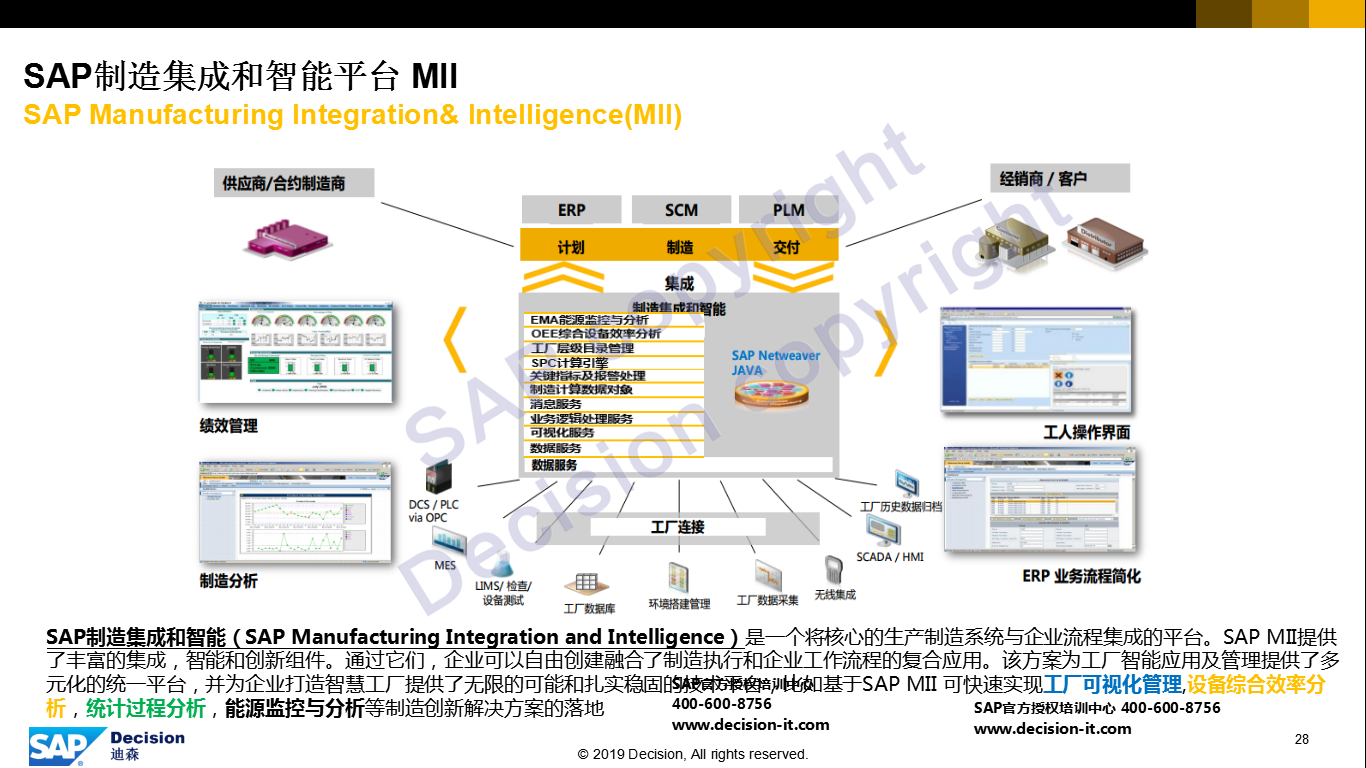

The functional positioning of SAP MES in the entire intelligent manufacturing. It is the central management platform for the entire manufacturing execution and control. It is divided into two modules: ME production execution management module, MII manufacturing integrated management module and PCo production equipment integration adapter that comes with the MII module. It is composed of SAP MES's PCo integrated adapter and integrated with production line equipment. Through PCo's prefabricated standard protocols, it can support many domestic and foreign DCS PLC and other systems and equipment. Currently, more than 85 protocols have been prefabricated. There will be more and more version upgrades in the future.

The production process and management is actually a production management cycle. Through the corresponding production plan, the production order is transferred to the MES through MII, and then the MES manages the entire production and execution process, and finally delivers the finished product to ERP for production order reporting. , in this process, the management of the machines and equipment used in the production process is also managed. Through such a complete cycle, the entire production operation management is guaranteed.

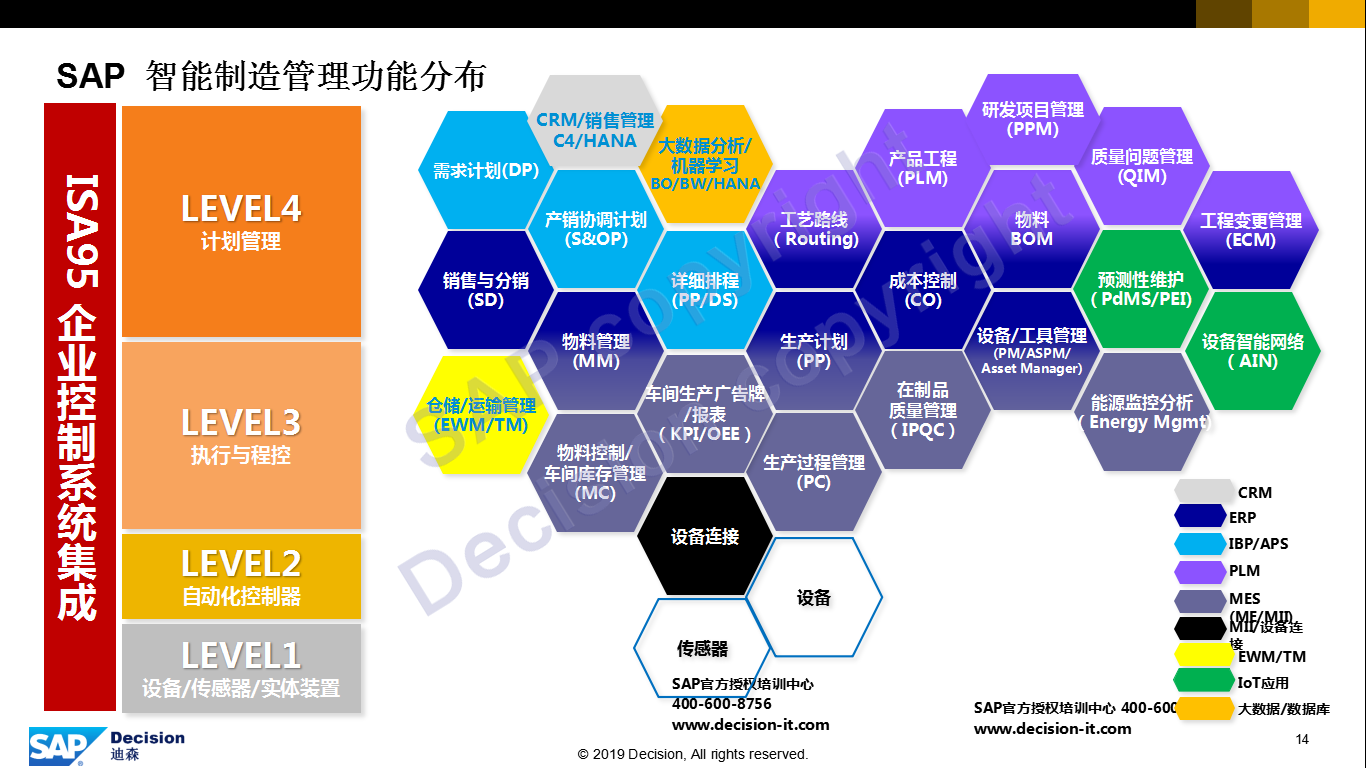

6.SAP intelligent manufacturing management function distribution

According to the distribution of SAP intelligent manufacturing management functions, according to the ISA95 enterprise control system integration standard, SAP currently has corresponding solutions at four levels from Level 1 to Level 4. In terms of functions, MES is dark purple. The functions of each system are connected together, including big data analysis and machine learning, PdMS, ECM and other products, which can be seamlessly integrated together to ensure that we are comprehensive from Level 1 to Level 4. The complete management layout of smart manufacturing.

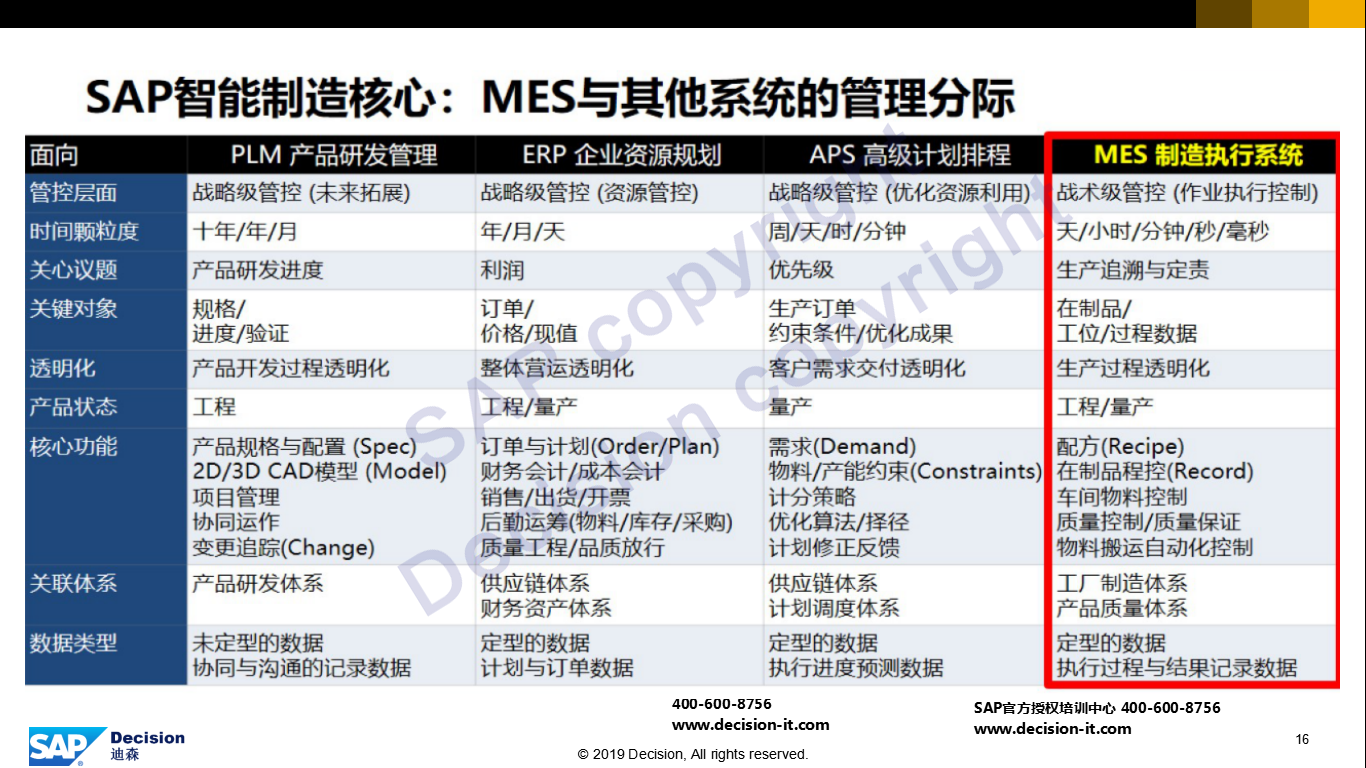

7. Management distinction between MES and other systems

In the field of intelligent manufacturing, the management demarcation between MES and other systems is also compared here. From each aspect: management and control level, issues of concern, transparency, etc., PLM products, ERP planning, The functions corresponding to APS advanced planning and scheduling and MES products are functionally differentiated.

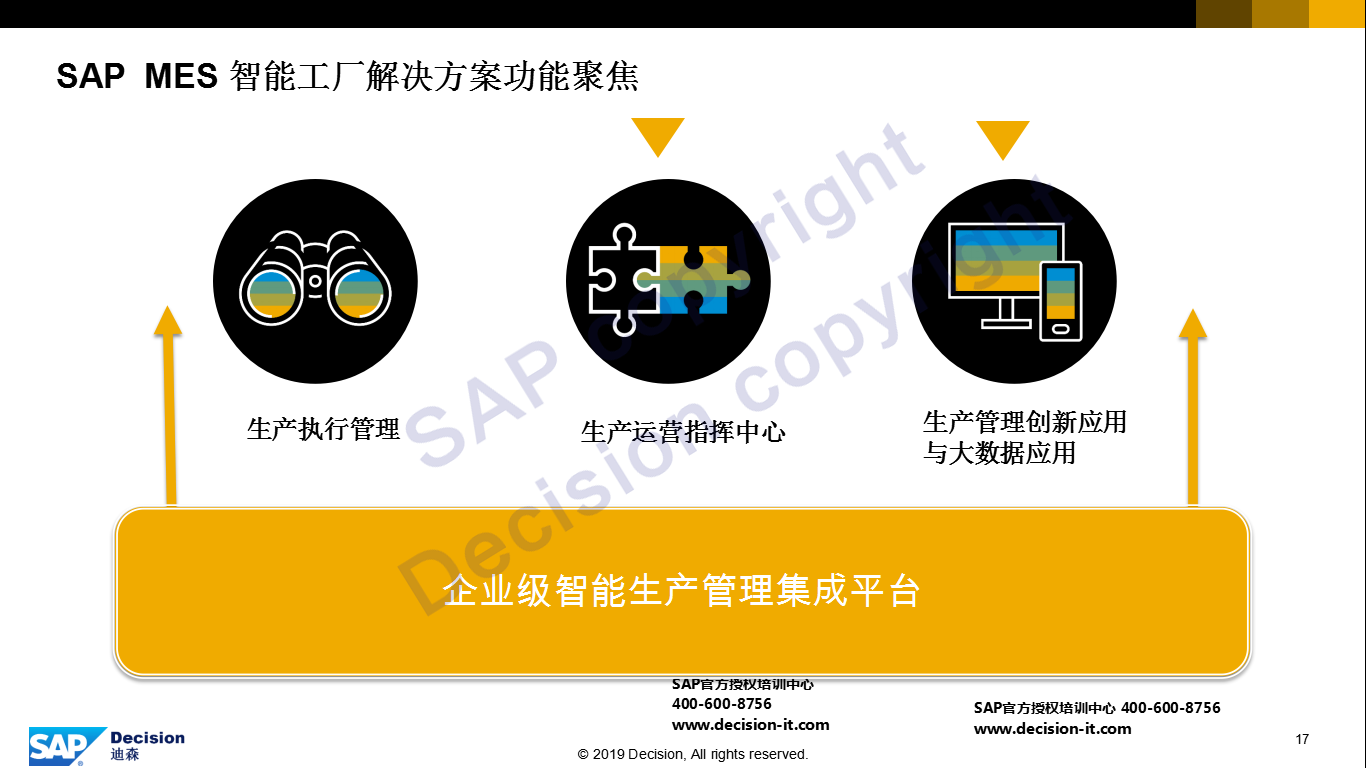

8. MES smart factory solution function focus

SAP MES smart factory solutions can be classified into three categories:

The first category is production execution management, which is MES in the traditional sense;

The second category is the production operation center, which manages the entire production operation and monitoring;

The third category is production management innovation and big data applications. Because the new version of SAP MES supports the HANA database, MES plus HANA makes many innovative applications of production management possible that were previously impossible.

9.SAP production operation command center

The production operation command center uses a unified integrated platform to monitor, report, analyze and manage an organization's daily production operation process and business results. Provide real-time monitoring of production processes and business process activities, identify abnormal and bottleneck states and events, use real-time dashboards for analysis and display, and assist in optimizing production business processes and business performance as well as management decisions.

10.SAP Manufacturing Integration and Intelligence Platform MII

SAP Manufacturing Integration and Intelligence is a platform that integrates core manufacturing systems with enterprise processes. SAP MII provides a rich set of integrated, intelligent and innovative components. They give companies the freedom to create composite applications that combine manufacturing execution and enterprise workflows. This solution provides a diversified unified platform for factory intelligent applications and management, and provides unlimited possibilities and a solid technical platform for enterprises to build smart factories. For example, based on SAP MII, it can quickly realize factory visual management and equipment comprehensive efficiency analysis. The implementation of innovative manufacturing solutions such as statistical process analysis and energy monitoring and analysis.

SAP MII supports group-level data aggregation, which can lay the foundation for benchmarking the production efficiency and energy efficiency of each factory at the company level, thereby facilitating future group-level management and control. It runs through the message integration, data integration and business integration of the enterprise planning layer, production execution layer and control layer.

▲SAP Overall Equipment Effectiveness (OEE), KPI management through pre-built business process execution:

- Based on the rich standard content of MII, a simplified version of production execution and calculation of OEE indicators can be realized;

- Two-way integration, downloading ERP work orders and transmitting back information on work reporting, material input, scrap, rework, goods receipt, equipment maintenance and other information in real time;

- Record the reasons. For all events that affect OEE indicators, the reasons need to be recorded for subsequent analysis and rectification;

- Real-time calculation and analysis, comprehensive equipment utilization rate, equipment utilization rate, equipment efficiency and quality efficiency;

- Friendly user interface design, touch-based cross-platform interface;

- Supports all types of factories, fully manual, semi-automatic, and fully automatic production environments;

- Discover and drive further improvement points based on obtained performance indicator data and corresponding root causes;

- Improve competitiveness, increase production reliability, and enable employees to continuously identify problems and take countermeasures by using OEE performance indicators;

- Promote the implementation of improvement measures and a closed loop of continuous improvement.

▲SAP Energy Monitoring and Analysis (EMA)

- Provide real-time data visualization of enterprise energy consumption – combined with production schedules and energy supply contracts, to optimize the use of water, electricity, oil and gas. Provide energy data analysis functions, further integrate OT/IT data, and expand into energy management and planning.

▲Reducing the burden on the existing MES system

▲MII integrates production operations, allowing MES to focus more on production execution

A large amount of data continues to be generated during the production process, and is divided accordingly based on the business attributes carried by the data, so that MES can focus more on production execution and ensure production operations; MII provides the information integration required for workshop operations and provides a wider range of applications.

- The station-passing data, core product traceability, and material consumption data required in the production and processing process enter the MES;

- Non-core product traceability data, processing parameters and summary data enter MII for data integration: SPC analysis, yield summary analysis;

- Equipment operation data, status data, and fault information generated during the production process are stored in MII for subsequent data integration, presentation, and analysis: equipment fault reporting platform, OEE analysis platform.

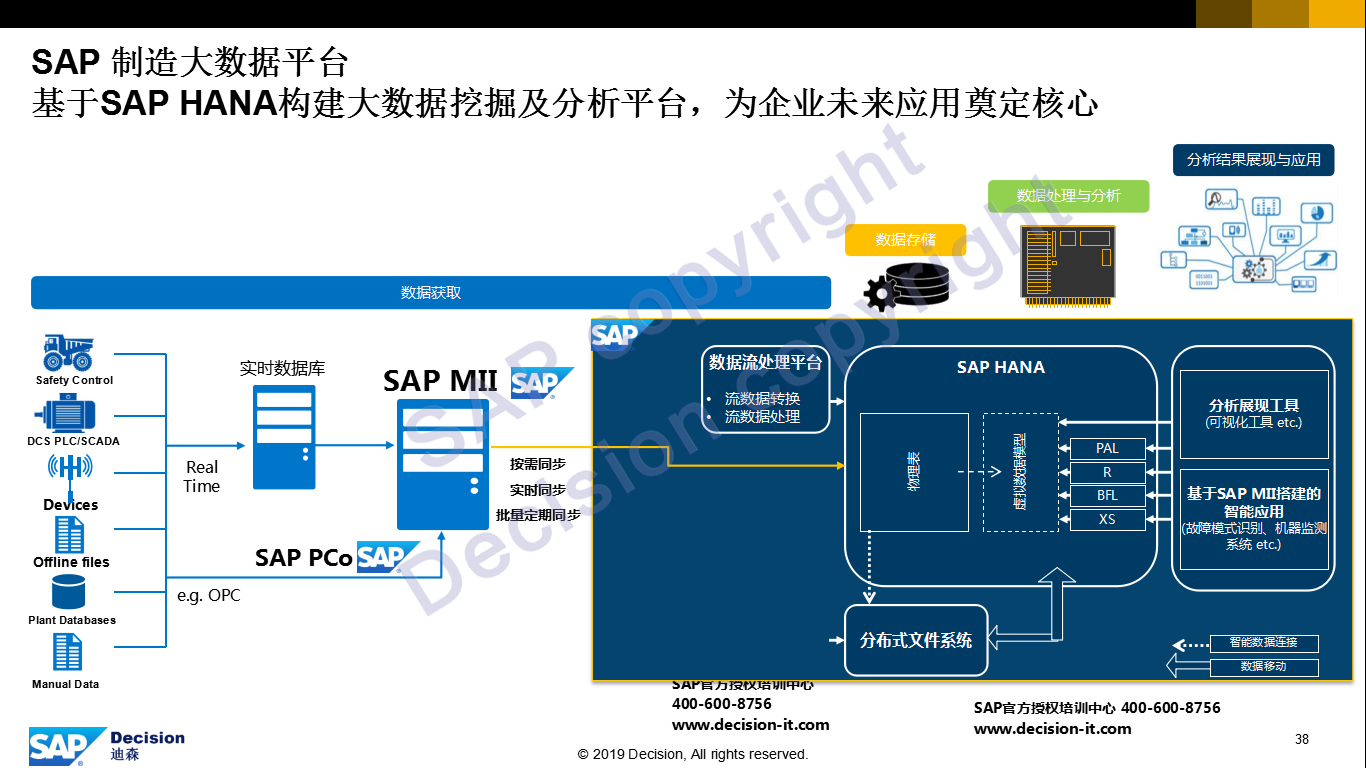

11.SAP manufacturing big data platform

In the future, the database recommended by SAP is HANA, so SAP MES can make use of some of HANA's performance advantages and powerful capabilities to make some innovative applications in production management.

Build a big data mining and predictive analysis platform based on SAP HANA to lay a core data platform for future enterprise applications. A unified factory-level data model obtains data from various systems and generates an industry-standard measurement library; it can expand and customize its own performance standards through KPI modeling; it uses HANA for advanced analysis, prediction, and machine learning algorithms to analyze different factors. The inherent connection between; cloud-based self-service reporting analysis platform and cross-platform access to data anytime and anywhere.

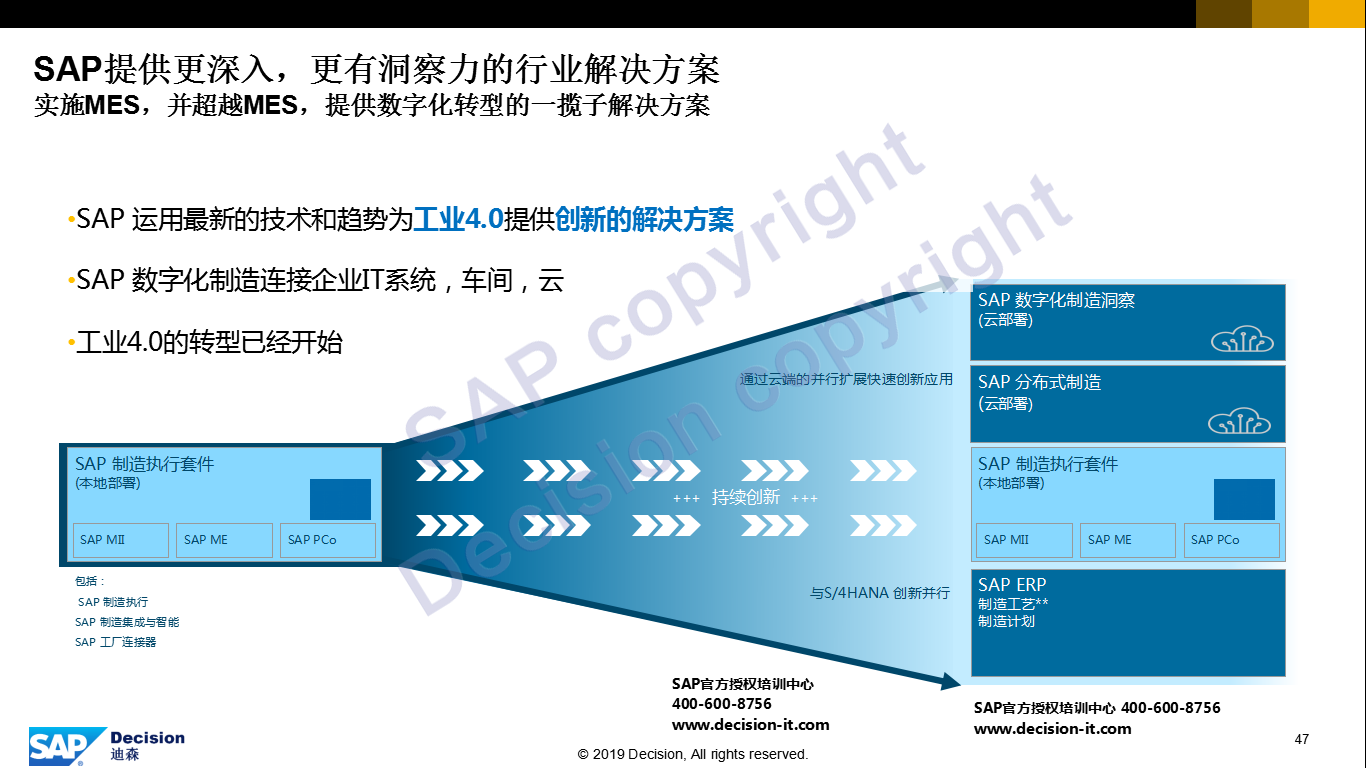

12.SAP provides deeper and more insightful industry solutions

SAP MES is not just an MES, it is a major platform in the field of production and operation management of the entire enterprise. SAP provides many industry solutions that are deeper, broader, and more insightful. It has completely surpassed the management field of MES.

With the continuous upgrading and optimization of SAP's S/4HANA, MES and HANA products, SAP's intelligent manufacturing management solutions will increasingly reflect its great value, and SAP will continue to integrate various advanced intelligent technologies integrated into the product. Make the solution more intelligent, comprehensive and flexible, so that the solution can truly help enterprises quickly move towards smart enterprises and make smart manufacturing within reach.

Statement: This article is an original article, and the copyright belongs to the author; the Decision public platform welcomes the submission of original articles. If you want to contribute, please send an email to: [email protected]

【Service Guide】

For more information on SAP courses, project consultation and operation and maintenance, please call Decision's official consultation hotline: 400-600-8756

【About Decision】

Global professional consulting, technology and training service provider, SAP gold partner, SAP software partner, SAP implementation partner, SAP official authorized training center. Thirteen years of quality, trustworthy!